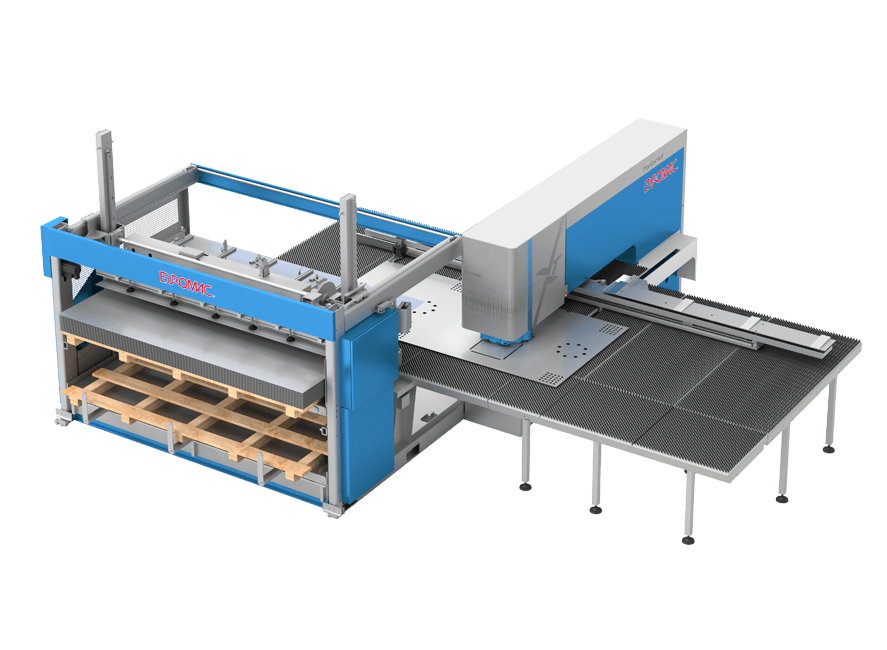

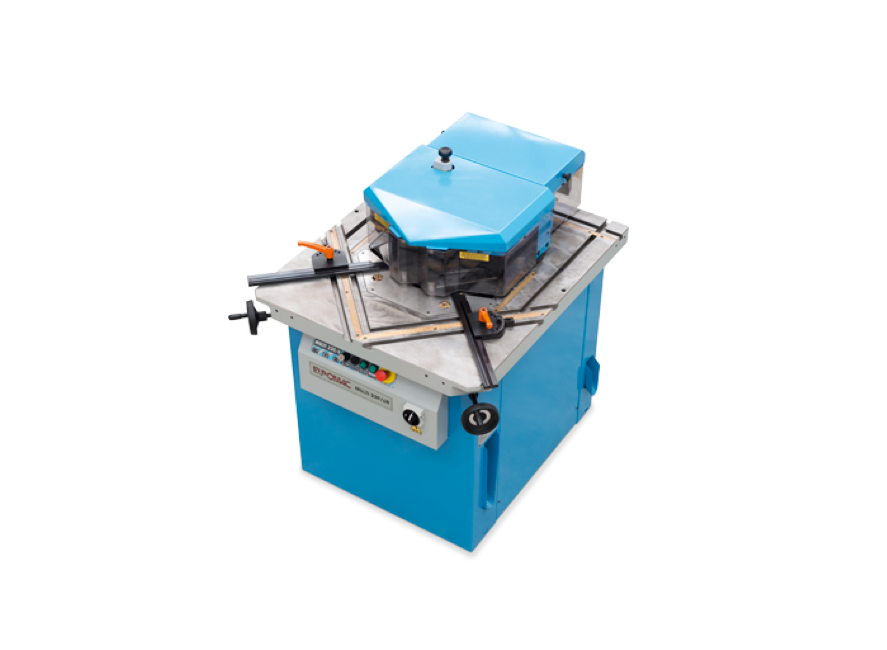

Innovation, reliability and productivity. If you had to define FX bend through three words would be certainly these. The Euromac range of electric press-brakes will promptly reply to your production requirements distinguishing itself for high precision and for elevated performances.

Innovation, reliability and productivity. If you had to define FX Bend through three words would be certainly these.

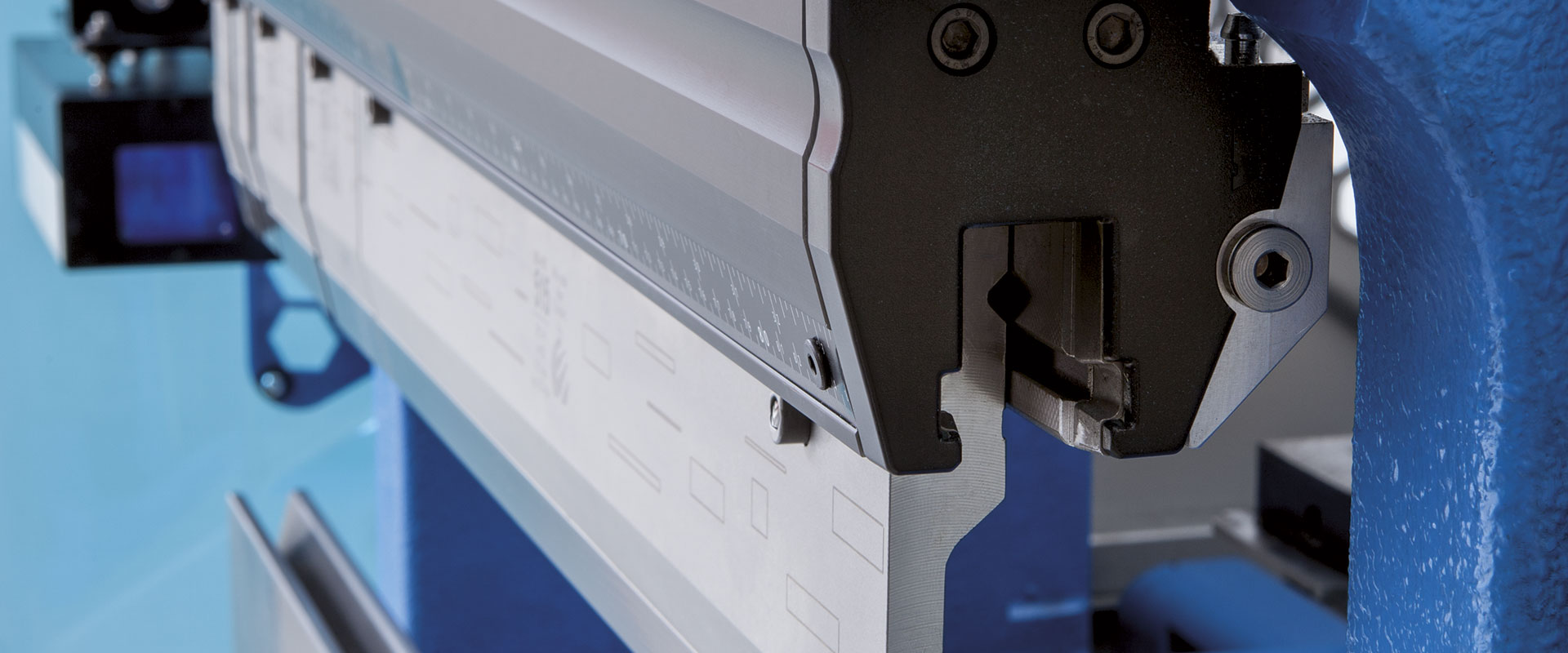

Innovation, because the force of the press is in extension during bending with the result of having greater strength and more precision in machining.

Reliability thanks to an extremely robust monoblock structure in Meehanite than any bending machine with an assembled structure.

High-level productivity with backgauges at 4 and 6-axis, fully automatic and with independent movements able to reach speeds of up to 1000 mm / sec which together with high decelerations ensure maximum productivity.

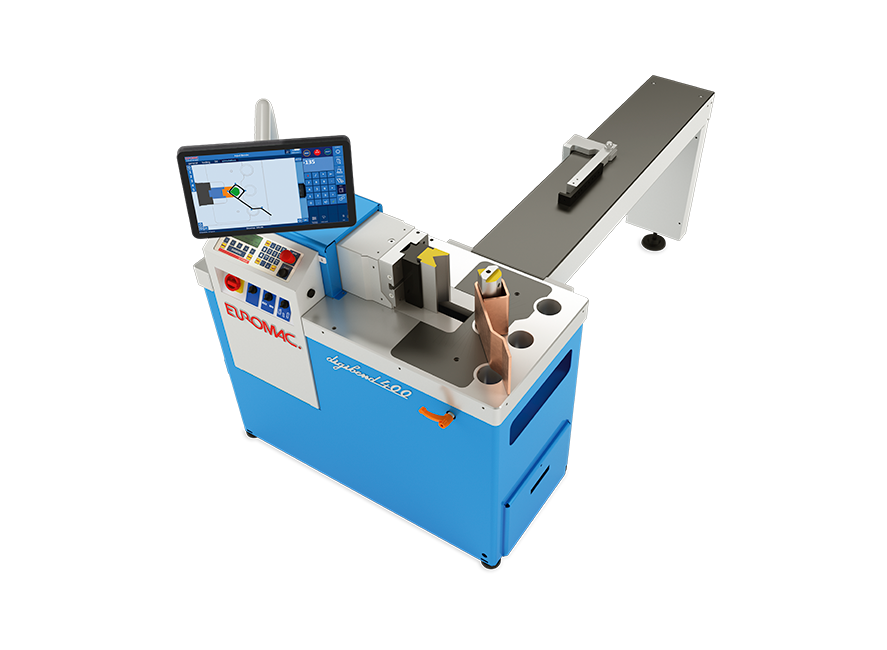

Control unit 21″

• Anti glare touch-screen LCD

• Water and dust resistant (IP65)

• Up to 9 hours battery power backup

• Windows® 10

• USB and WiFi connection

• DXF import files

• 2,5 D Graphic visualization

• 3 D Graphic visualization (optional)

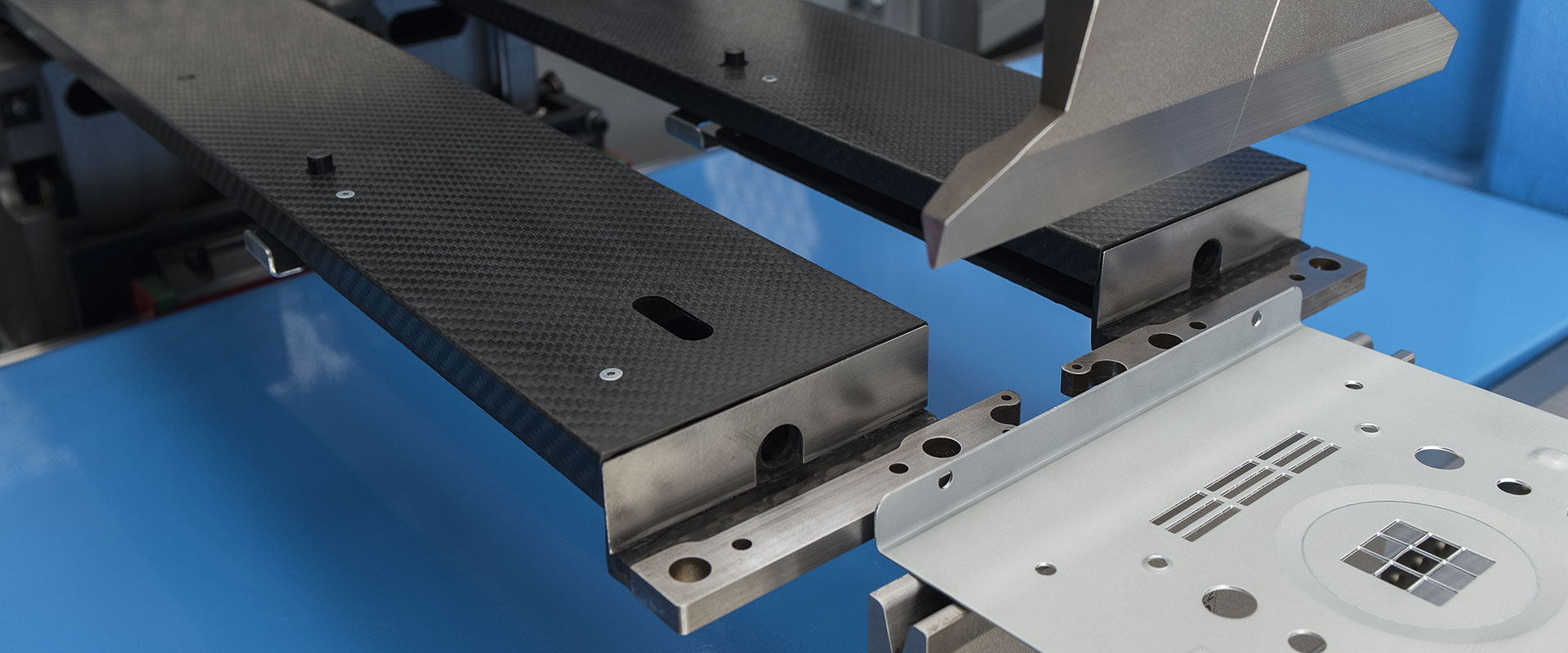

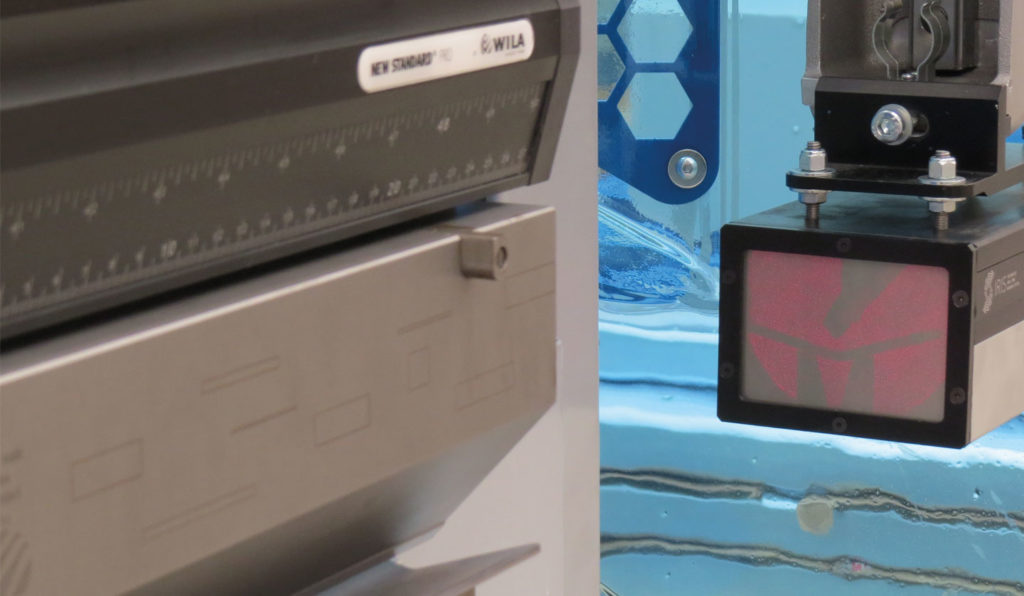

Tools

Promecam (European)

- Standard configuration:

- Upper tool holder with maual clamping system and quick lever (no tools needed)

- Lower tool holder with manual clamping system and quick lever (As Optional configuration: is possible to have a lower tool holder compatible with Wila and Promecam tooling with manual crowning system).

Video

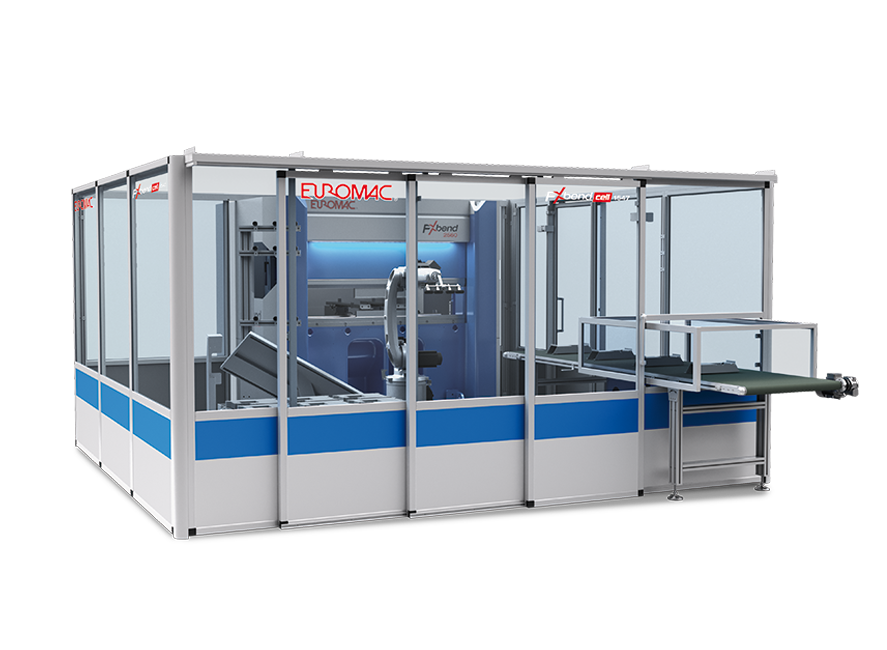

Optionals

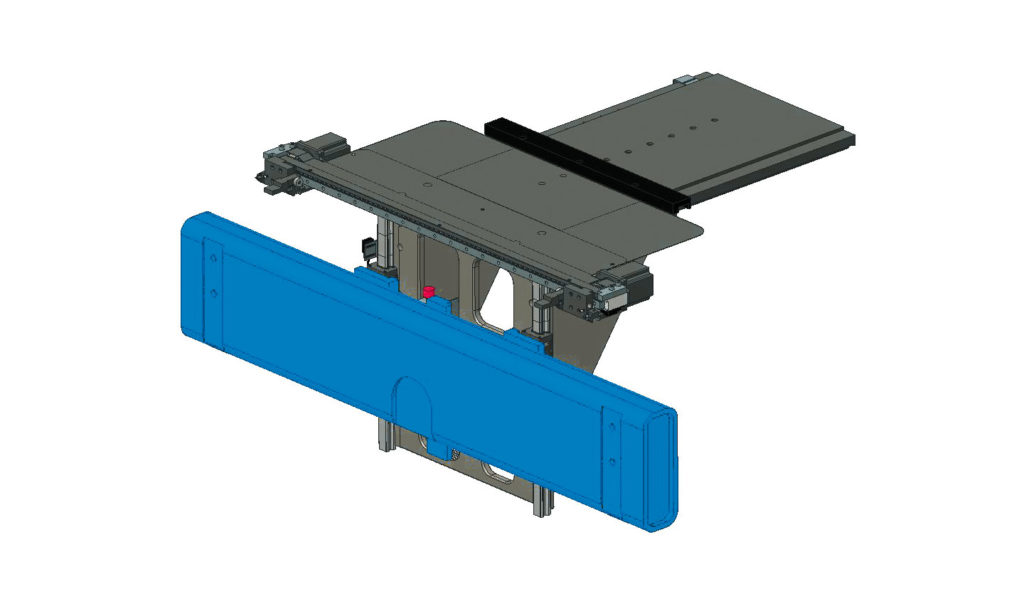

4 Axes Backgauge

Fully automatic and programmable

X, R and Z1 and Z2 axes. R axis stroke 180mm