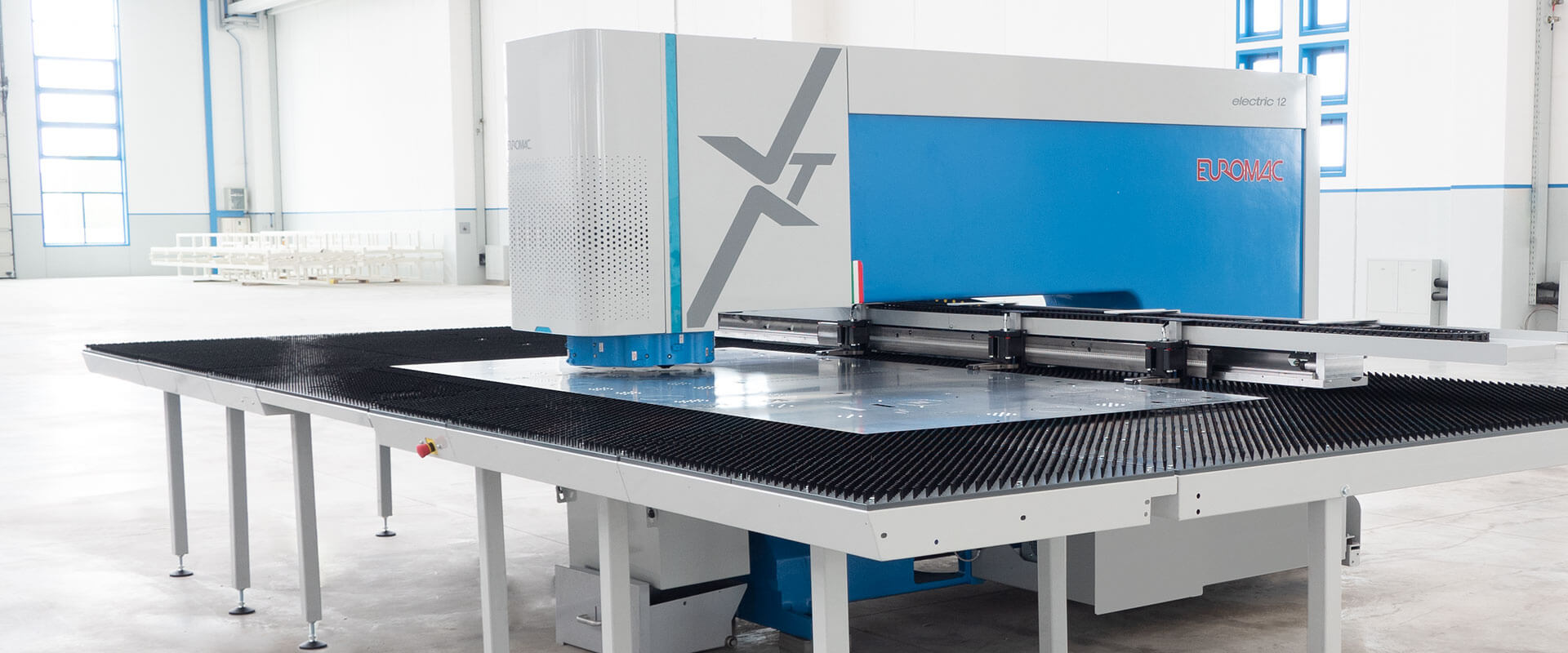

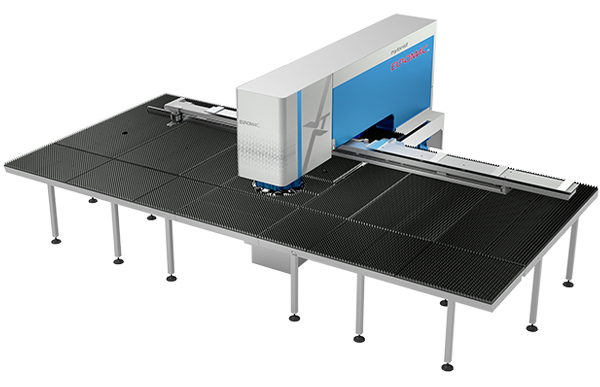

The constant research and technological innovation has allowed Euromac to create a range CNC punching machines that are performing, highly productive and with the lowest running costs. We offer numerous and versatile configurations that will satisfy all of your production needs, from the small to large industry optimizing whatever your requirements are.

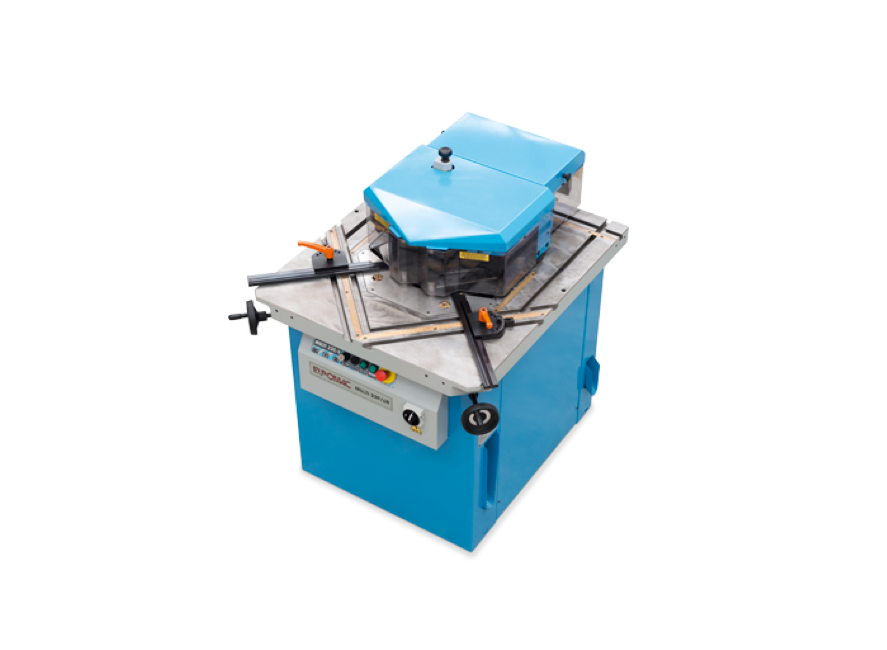

The structure of the Euromac range of punching machines consists of a Meehanite® standardised spheroidal cast iron monobloc casting which has a material tensile strenght of 700N / mm2, designed with the FEM method (finite element method). The frame structure of the machine has been increased in size which allows the machine to operate at higher speeds ensuring greater stability and therefore working precision.

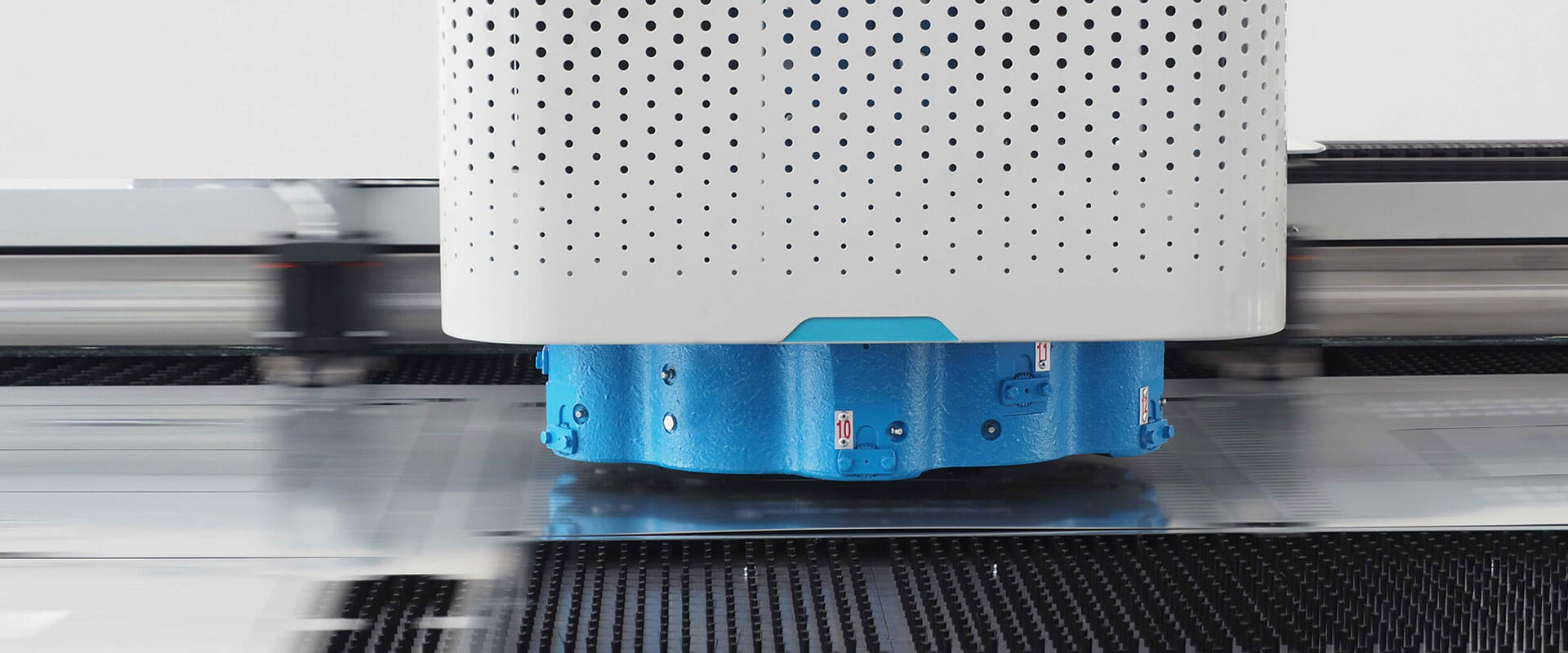

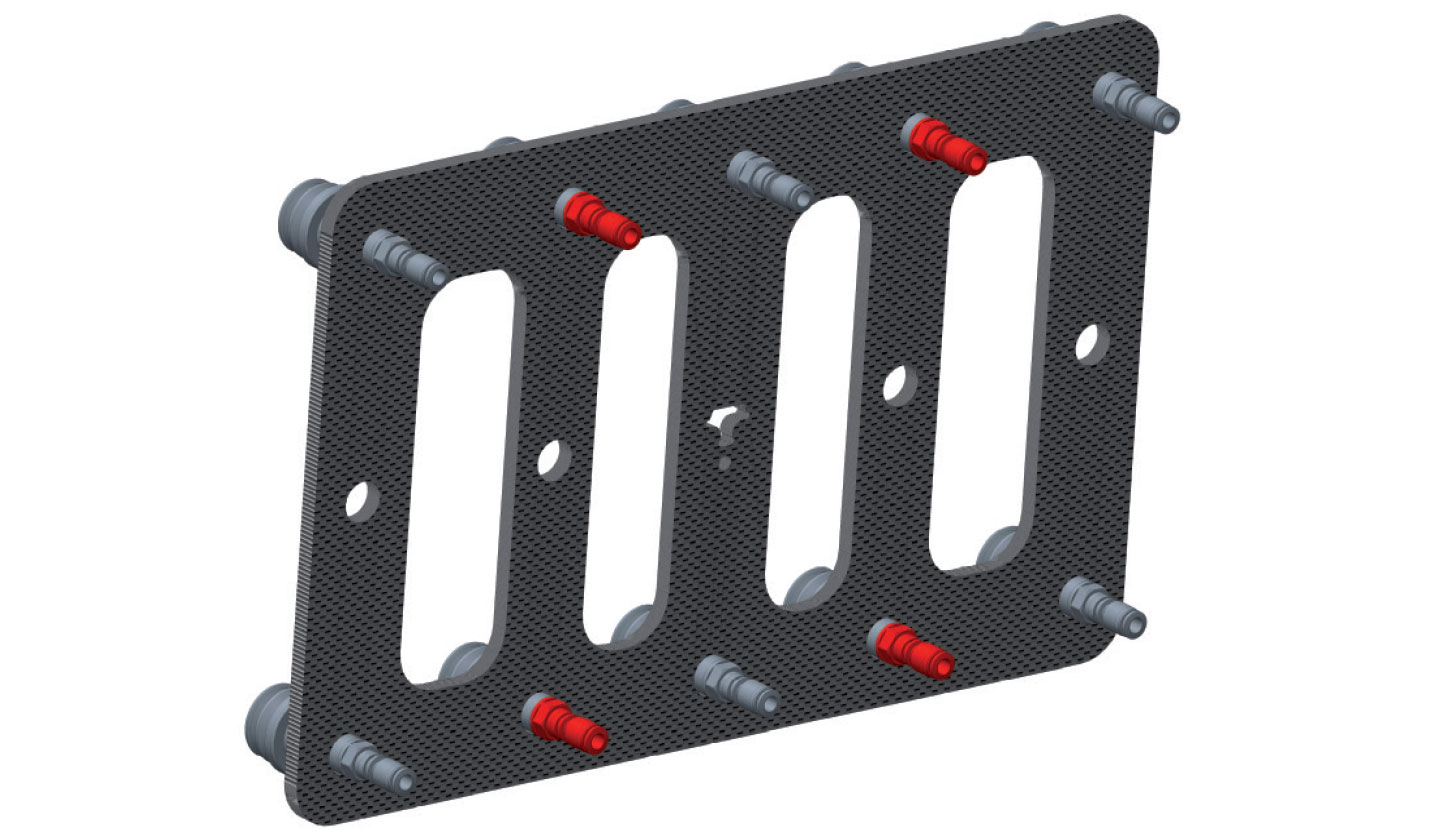

The patented AUTOINDEX system of direct transmission rotation of the stations has a reduced number of mechanical components so as to guarantee strength, greater reliability and precision, with less maintenance.

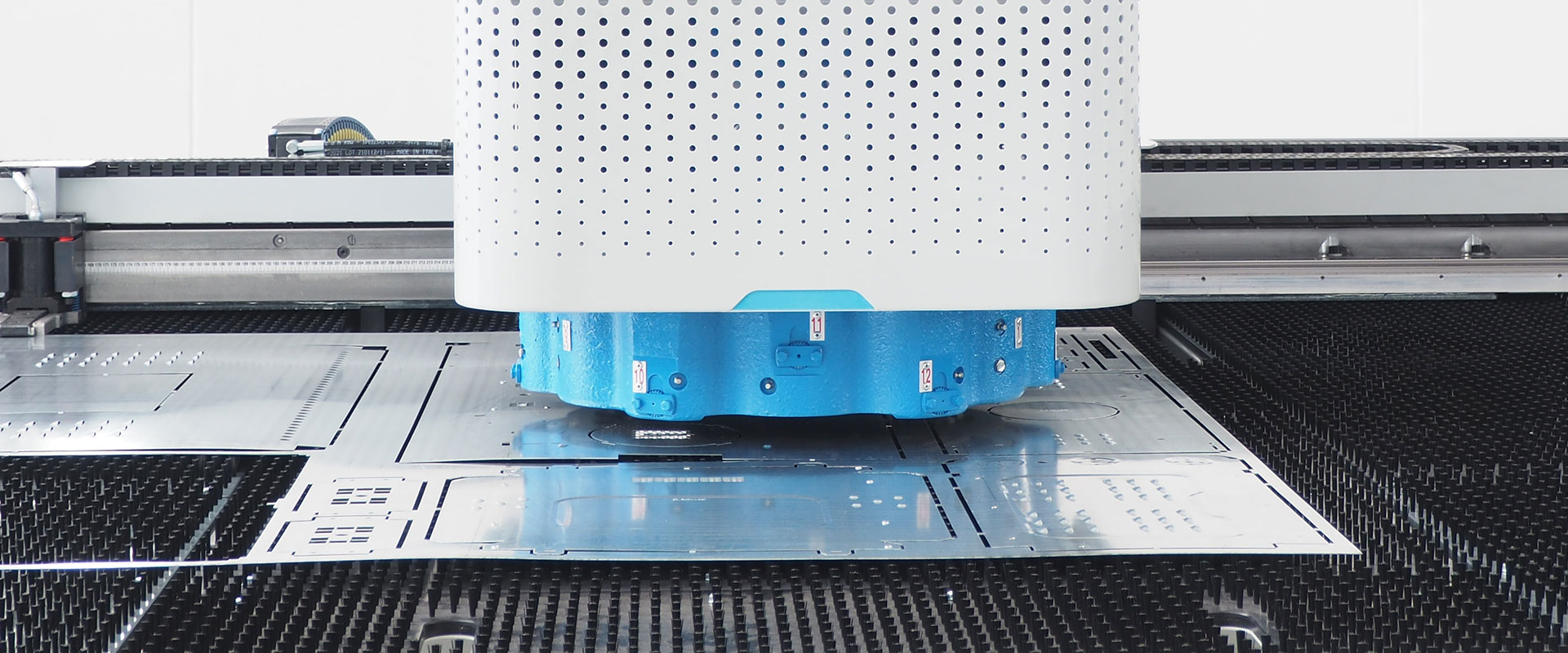

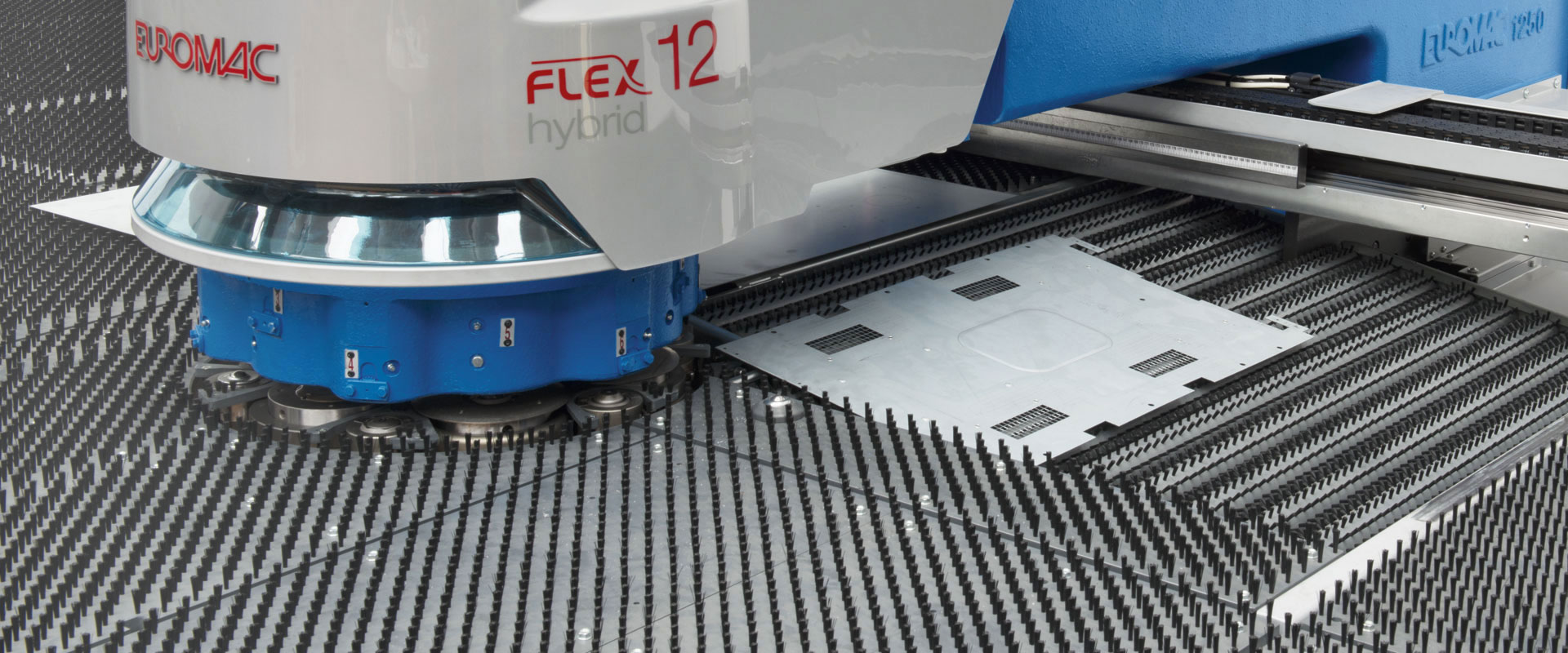

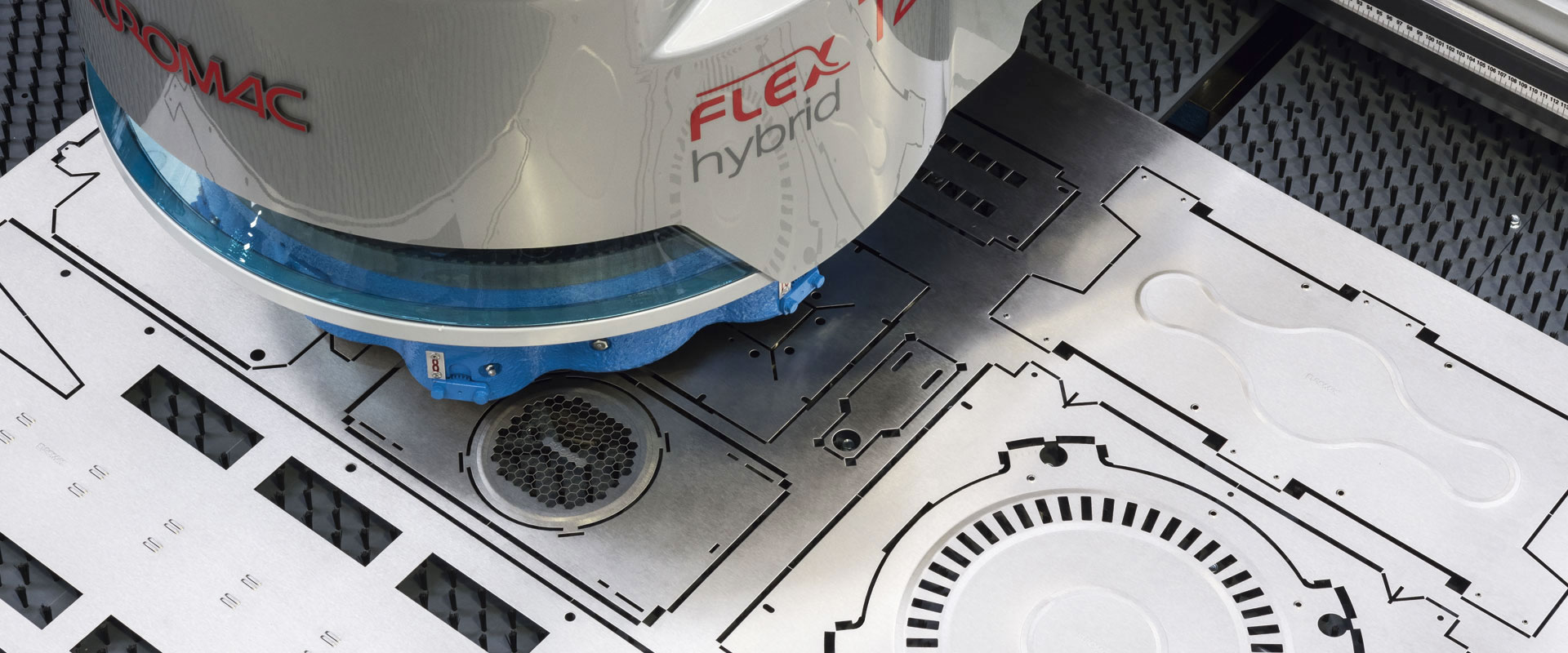

Electrical or hydraulic system? Why not get the best of both? Our range of punching machines introduces the FLEX system, which combines the power of hydraulics with the precision of the electronic control, in addition to obtaining a low electrical consumption, in fact on some machines where the FLEX system is present, only 8.5 kw are required with an average consumption of 4.5 kw in punching.

Tools

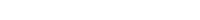

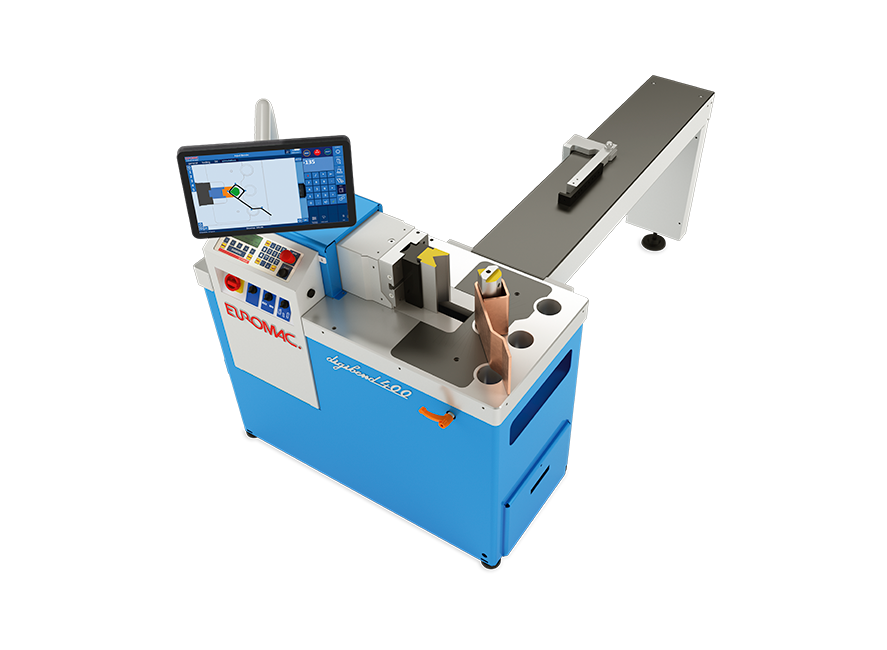

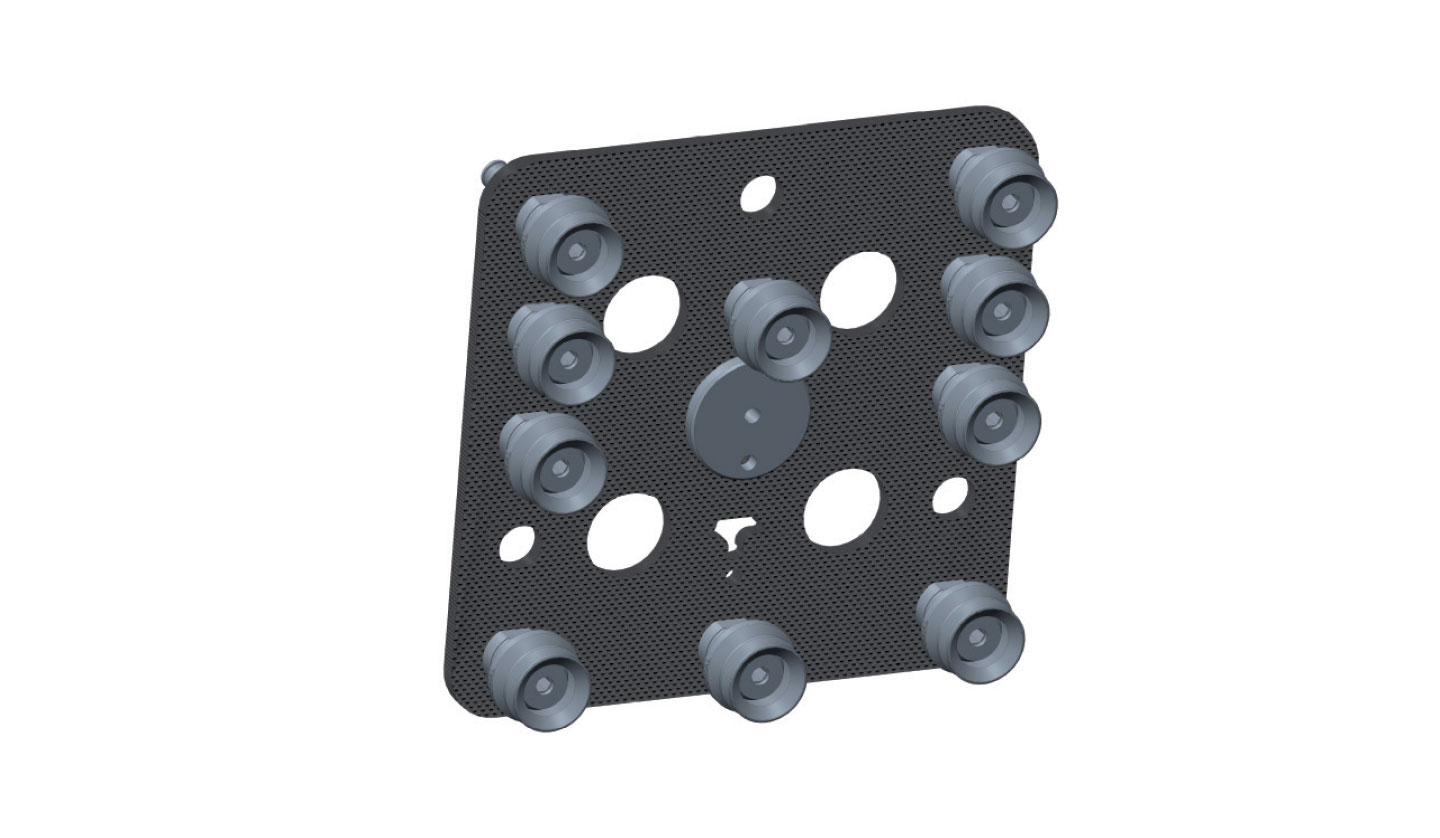

FMTE 10

- 8 tools up to Ø 12,7 mm (A Type)

- 2 tools up to Ø 24 mm (FMTE6 Type)

- Adjustable punch length up to 9 mm grinding life

- Full guided punches

- Up to 22 tons – Maximum thickness up to 6 mm

- Antimark magnetic kit option

- Adjustable striping spring force according to material and thickness

Video

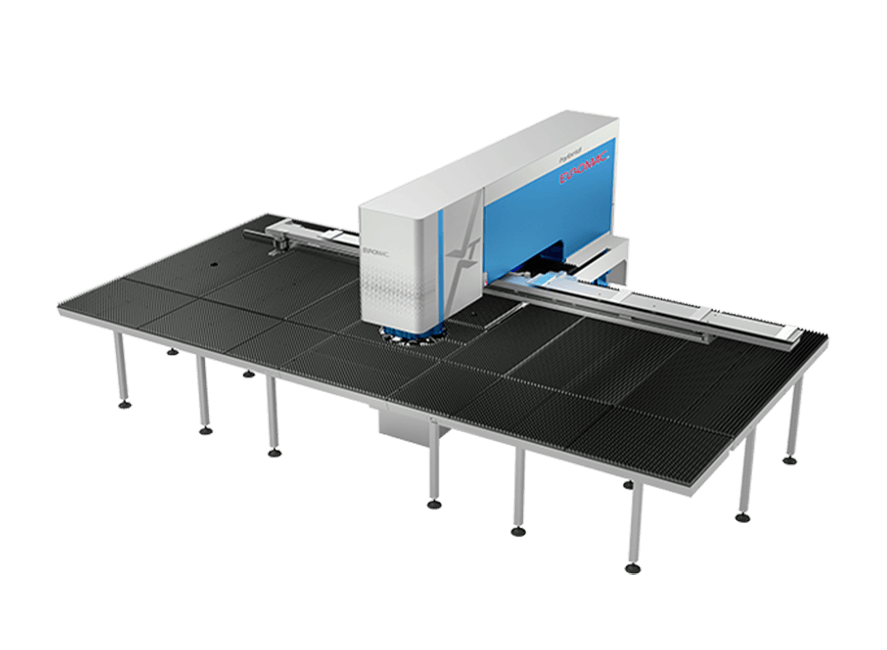

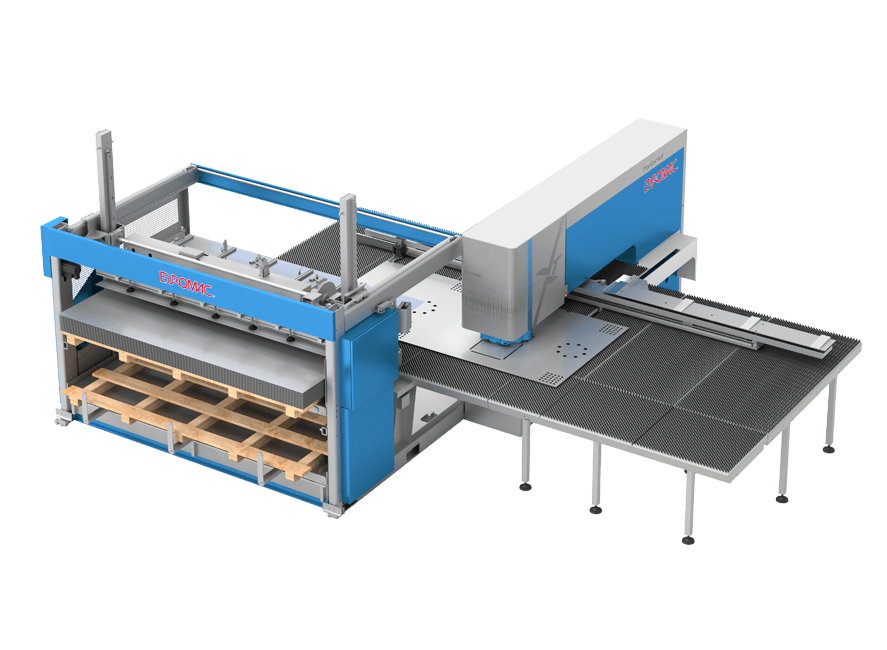

Optionals

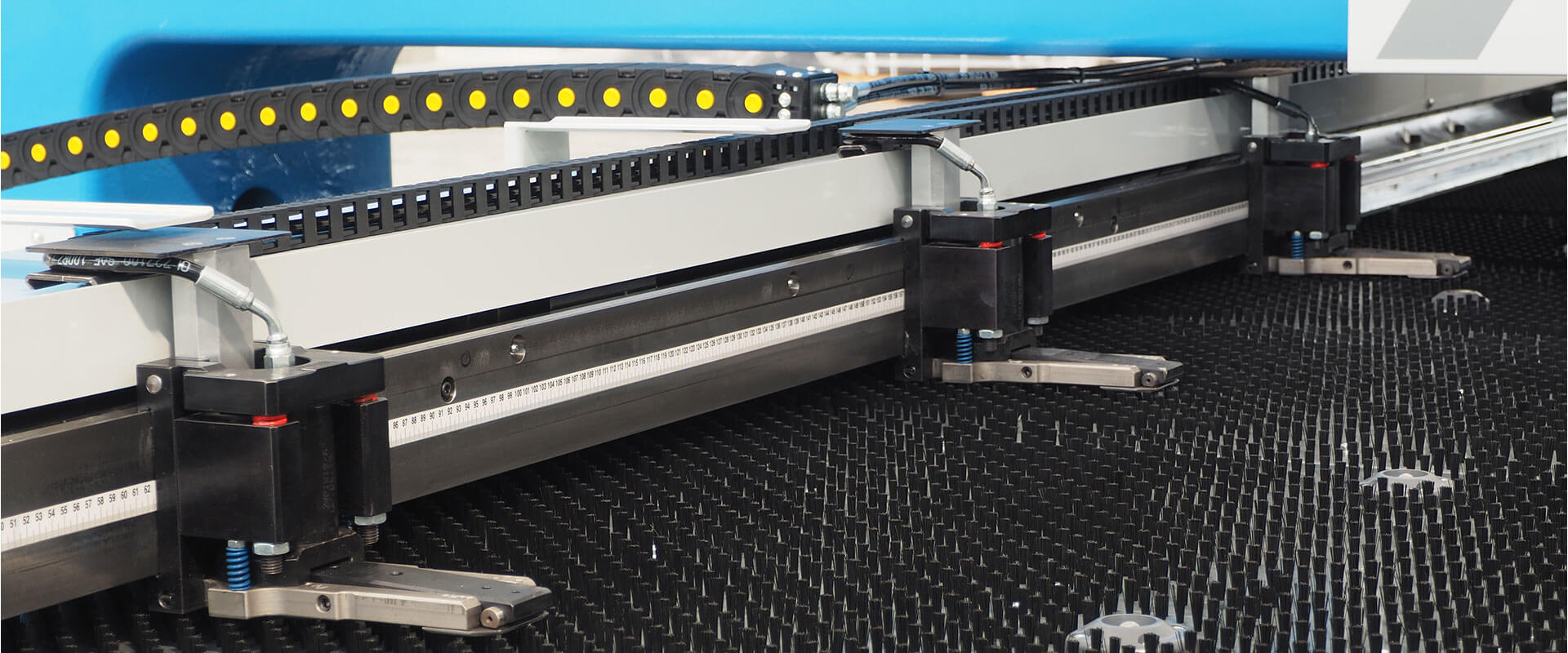

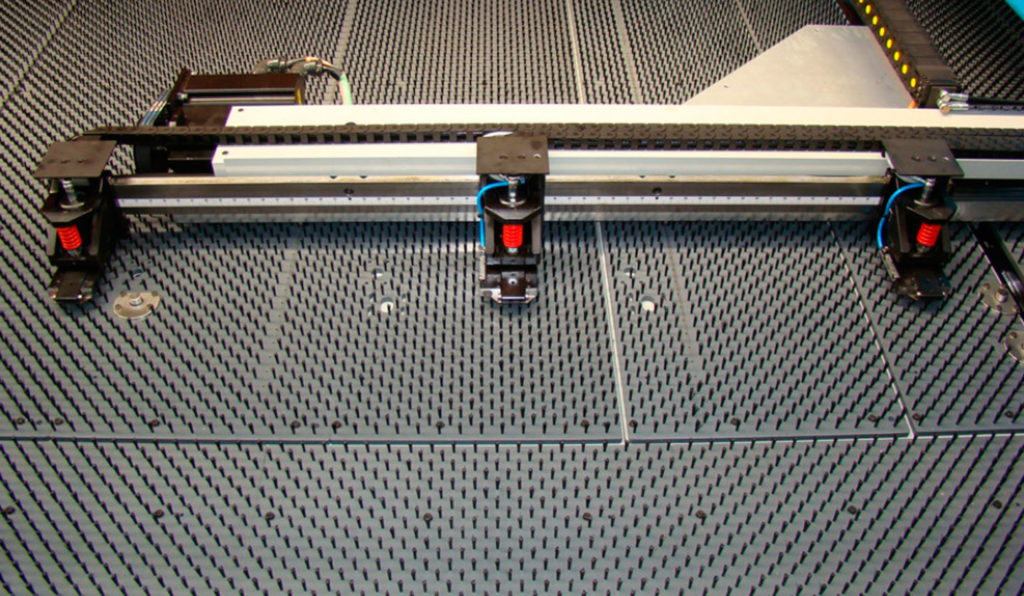

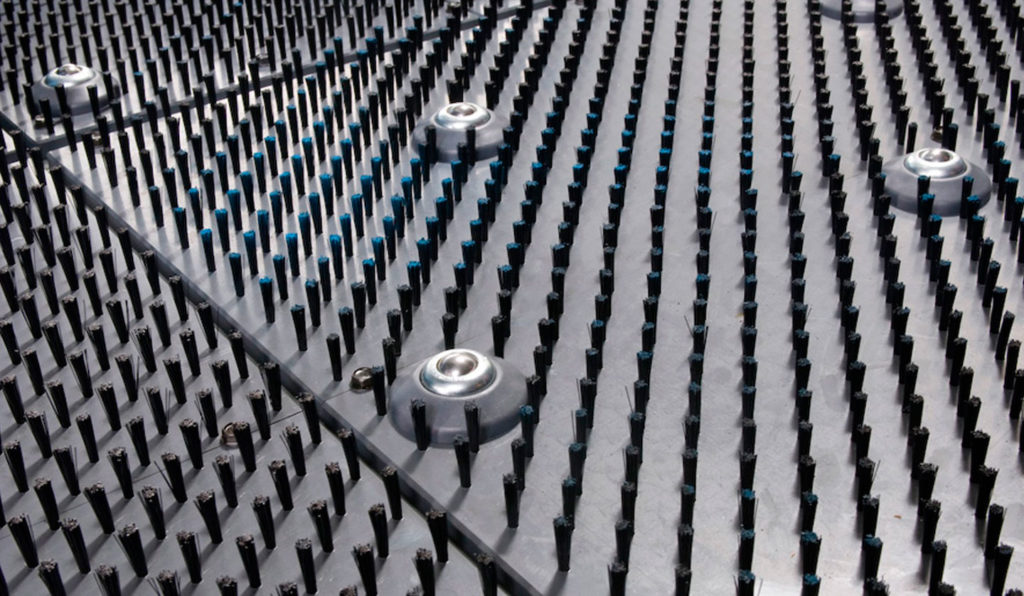

Combined brushes and balls tables

Our tables are equipped with Brushes to evitate to mark the sheet during the moving,we can make a combination with balls, recomended in case of sheets over 50 kg.