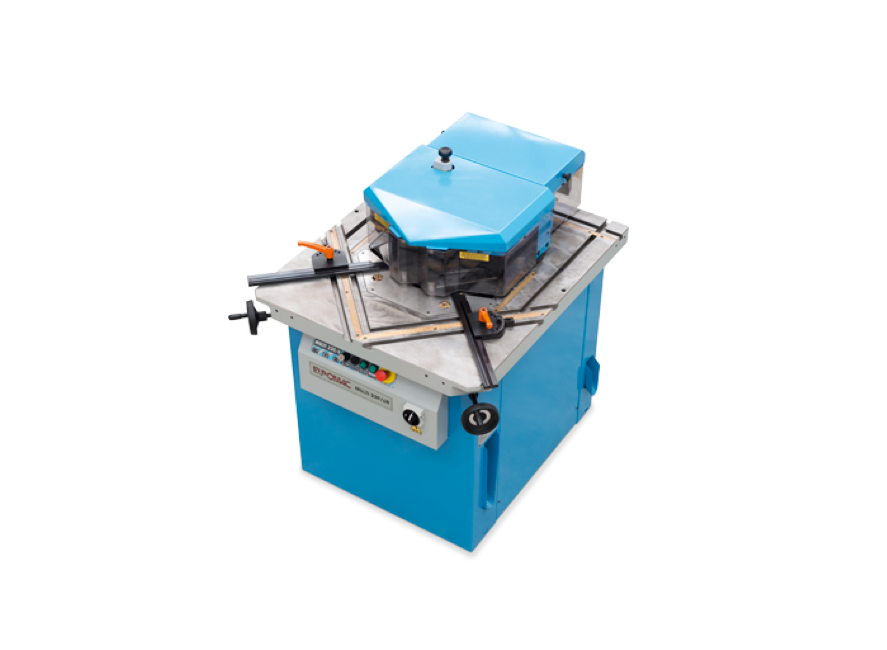

Whether you choose a fixed angle notcher or a variable angle notcher this one of a kind workhorse has features beyond any other in its segment.

The ultra rigid nodular cast iron monoblock (Meehanite®) casting guarantees our customers the best blade alignment and tool life in the industry.

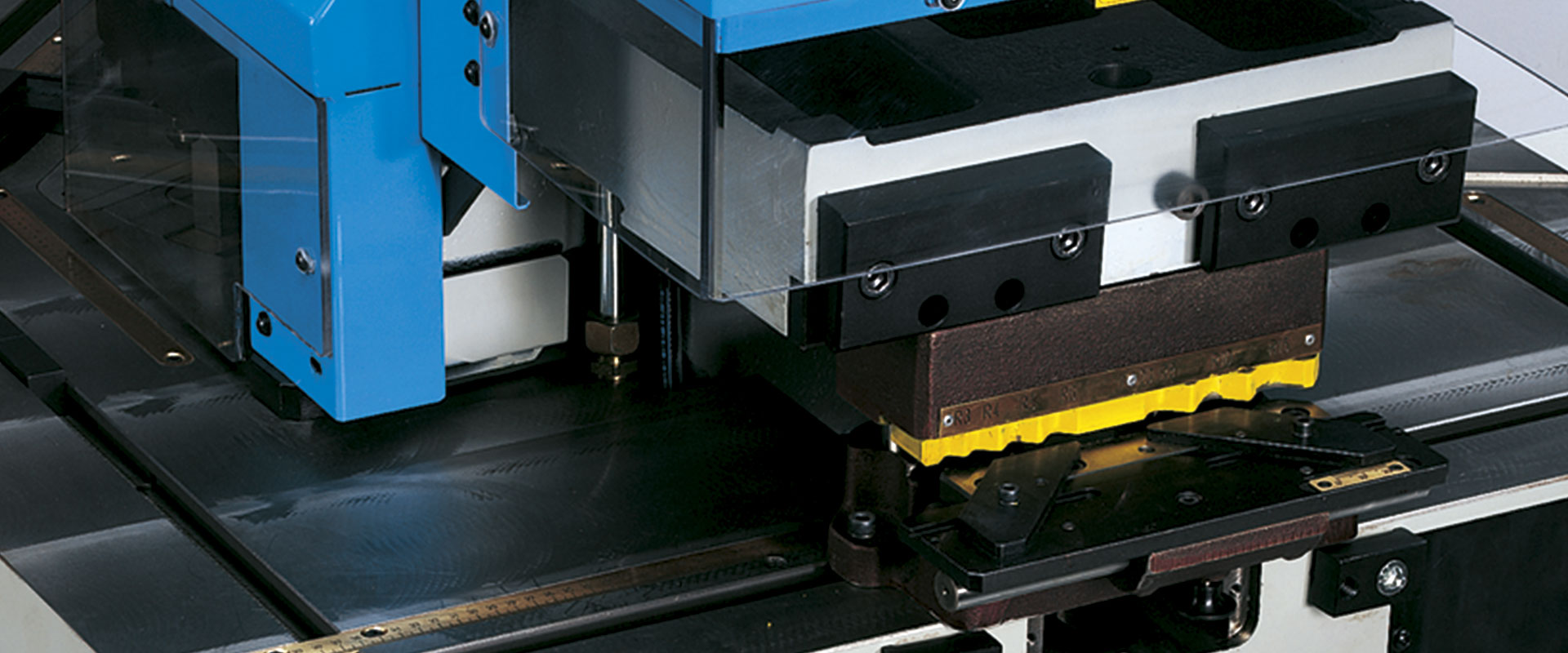

Automatic blade gap adjustment (European Patent n. 1.214.004), to ensure perfect cuts with different thicknesses (from 1 to 6 mm) and types of material with no burr, no time loss and no manual interspace adjustment.

Absolute rigidity of the notching unit monoblock ensured by two Meehanite 650 N/mm² steel castings joined together in a monoblock with three guides, two sides columns and a central guide.

The hydraulic clamping acting on the blades with 2 hydraulic cylinders ensures the positioning of the selected cutting angle

Security device: when the blades are in unclamping position, the machine cannot perform notching operations.

The monoblock construction together with 3 guides guarantees a long trouble free machine life. No other technical solution can be compared to the results obtained by Euromac machines.

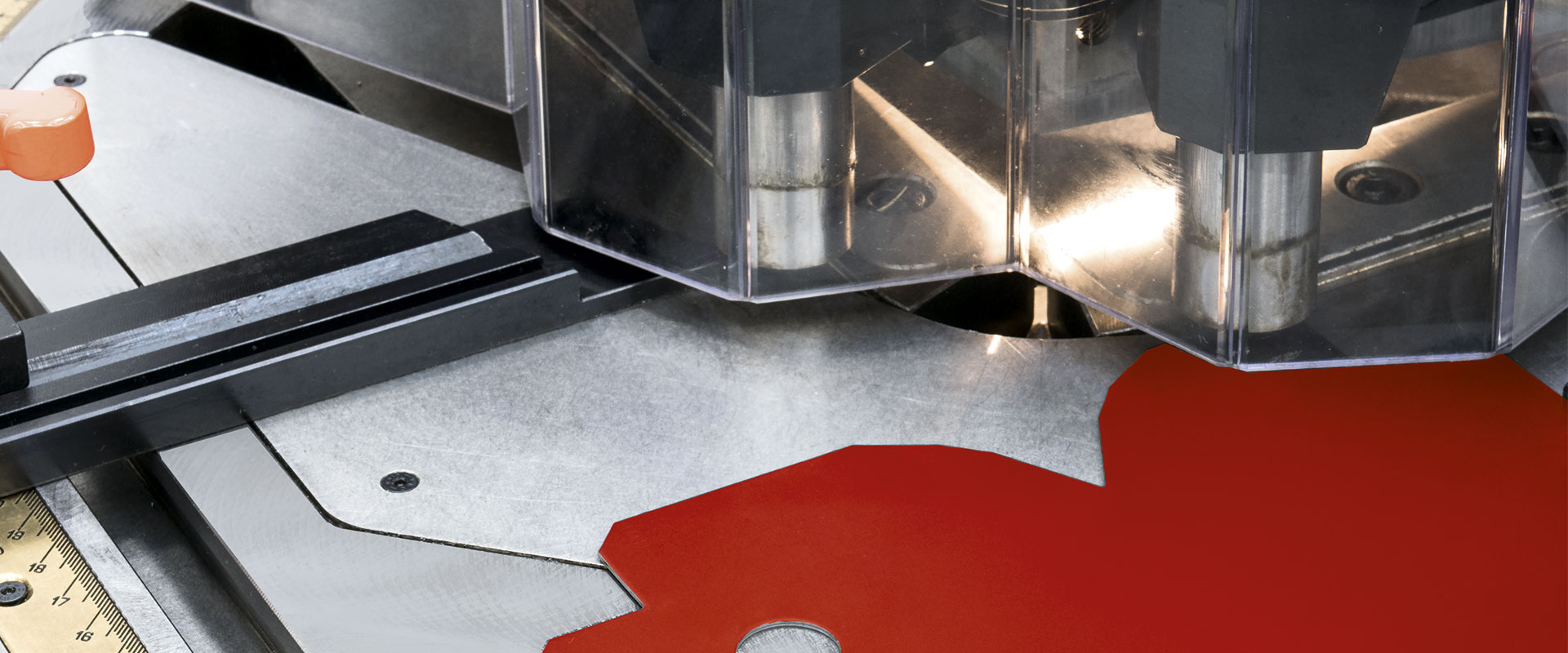

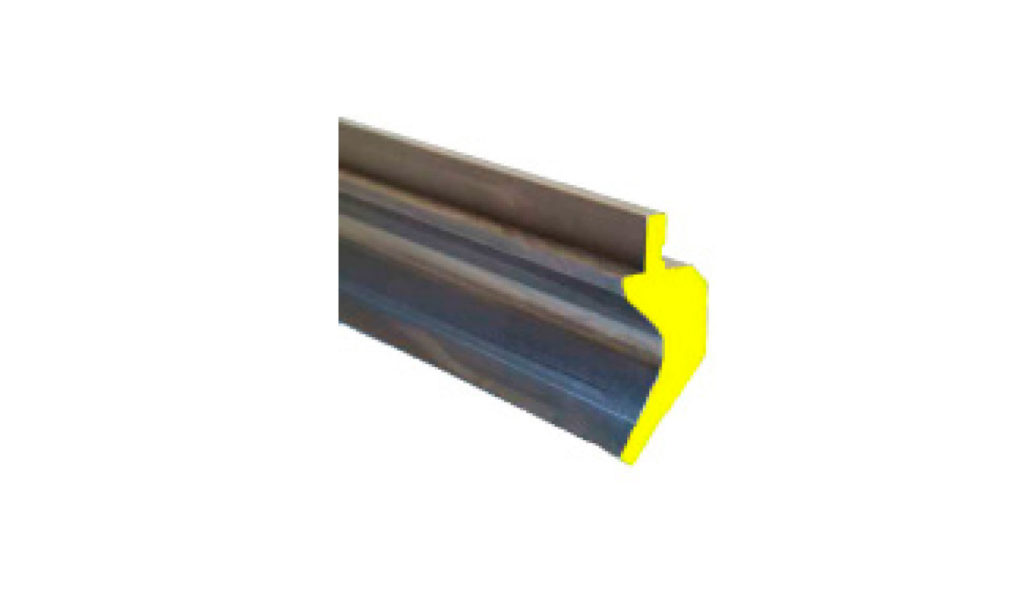

Reversible blades with possibility to choose positive cutting (starting to cut from the front adge) or negative cutting (starting from the rear side). On all VA models reversible blades at 30° positive and 60° negative are standard assembled

Selector for functioning in single step or step by step

Shearing function for cutting using a single blade with internal depth stop rod

Step by step cut with no length limit and with no interruption of the cutting operations thanks to the guide (zero setting) aligned with the front edge of the blades.

The stroke adjuster enables to limit the stroke and to increase the number of notches per min. for cutting low dimensions (with positive blades)

Protection of the cutting area guaranteed by a robust Macrolon shield allowing a perfect visibility of the protected working zone

No need of lubrication for central columns and cental guides

Tools

Optionals

Internal depth stop rod in cutting head c/w bracket

Internal depth stop rod in cutting head c/w bracket for VA 220/6R & VA-MULTI 220/6R