Our criteria for a product is excellence

Engineering

From mechanical design to software development, from documentation to application research, an expert team of engineers employs the latest available computer-aided technologies to continually improve our existing products and create new machine tools. The information created in engineering is integrated on our networks and is seamlessly available for production and customer support.

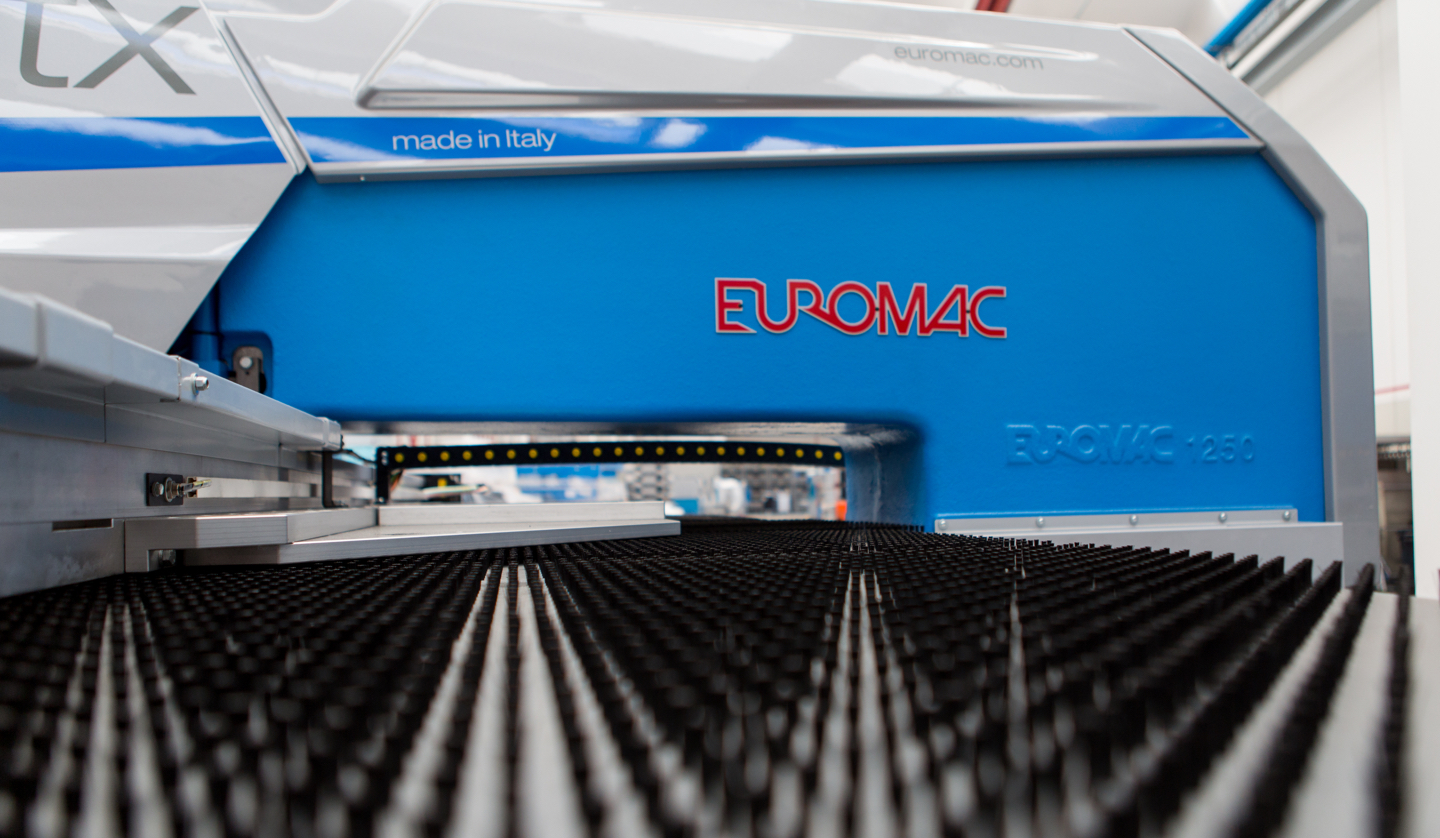

Foundry

Complete monoblock structure cast in normalized nodular iron (Meehanite®) with a tensile strength of 650N/mm2 for superior rigidity and dampening. These large structures are then machined in a single set-up on large working- envelope CNC machinery centers, featuring pallet rotation and automatic tool change. This results in higher quality and lower cost – both benefiting you.

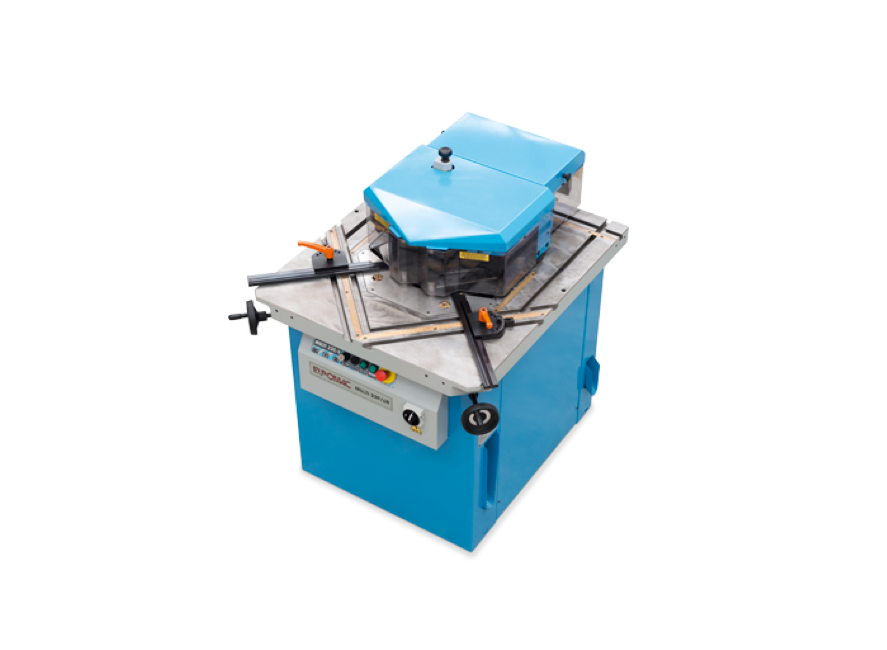

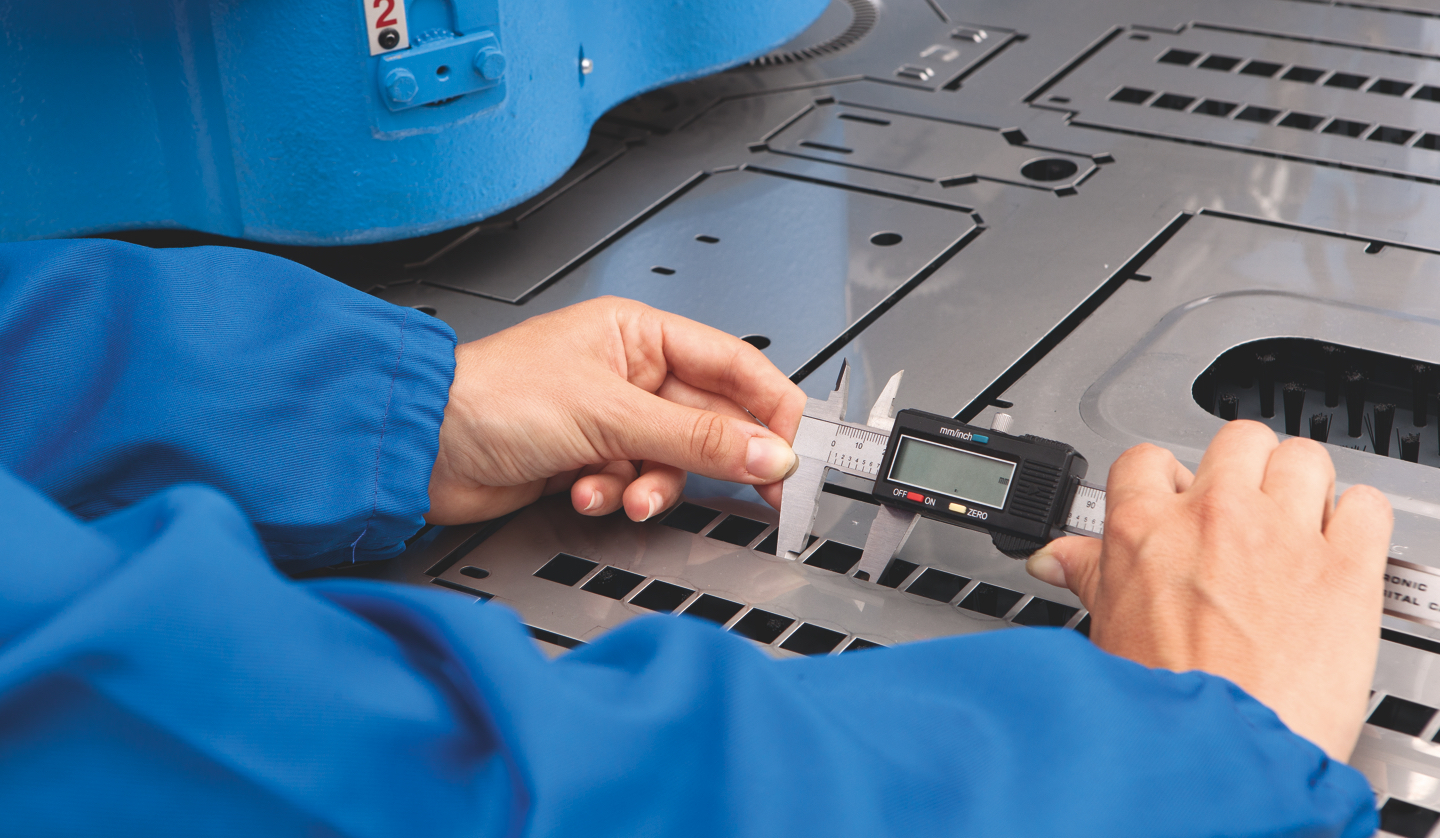

Products assembly and testing

Products assembly and testing We control our entire manufacturing process from foundry to final test. This allows us to deliver a high-quality product, which is extremely competitive both in capability and reliability, as well as price. The standardization of components the care in design allows us to produce assemblies and components in large runs on continuously updated and replaced machining centers, further improving the economics of a EUROMAC machine.

The principles of state-of-the-art manufacturing are driving both our product design, as well as our own manufacturing operations. We also believe in producing a quality product in a quality environment. Well illuminated, clean, friendly assembly halls are just one example of how we improve our high flow assembly lines.

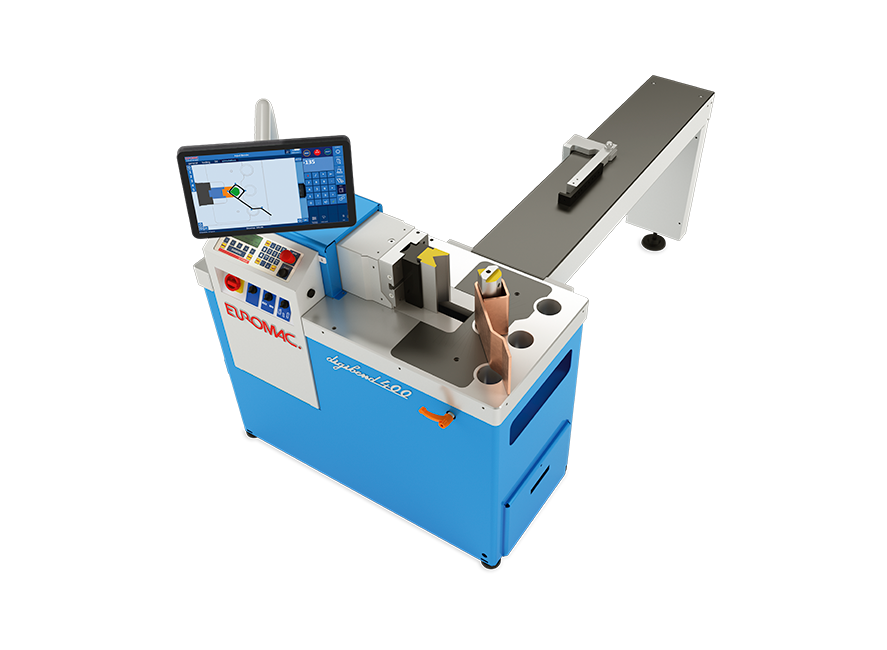

Machining technology

CNC Centers for vertical and horizontal machining, with tables and automatic tool changers. All worldclass machining centers.