How much does it cost not to buy a Euromac machine?

How much does a sheet metal processing machine cost? You are probably thinking of the figure your Procurement Department has negotiated with the supplier.

But this figure only accounts for part of the costs you will face.

Today we want to tell you about the other costs.

Don’t allow energy to eat away at your margin

The first additional cost is energy.

Automation now enables sheet metal working machines to run for increasingly longer periods of time.

This increases the number of parts produced, and also energy consumption.

A normal hydraulic press brake consumes around 14 KW/h, costing almost €8,000 in energy alone, every year.

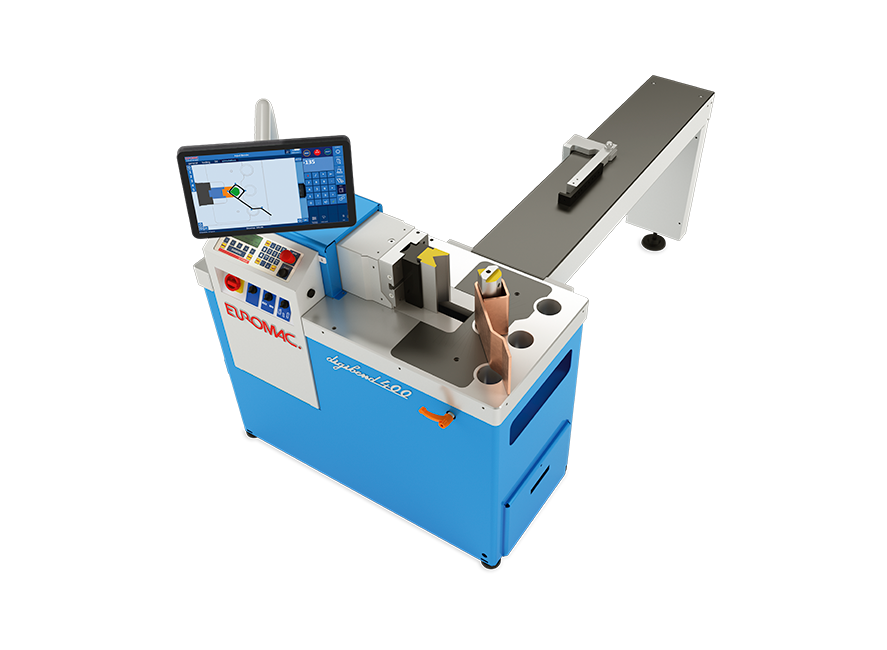

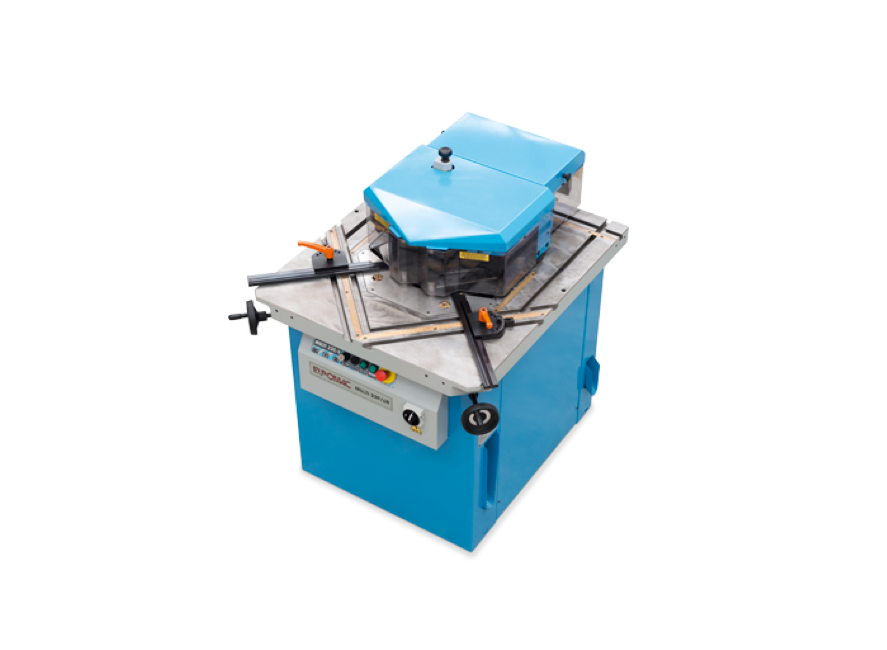

One of our FX Bend machines, on the other hand, consumes on average 2 KW/h; hence, you can run it for 7 years for the same amount of money!

And what about the cost of wear, maintenance and spare parts? What if there were none?

The second additional cost is maintenance.

Parts wear out and oil has to be changed. Moreover, regular maintenance is required to keep the machine in perfect working order.

All this has a cost. About €2,000, every year!

This is the case of a standard hydraulic press brake.

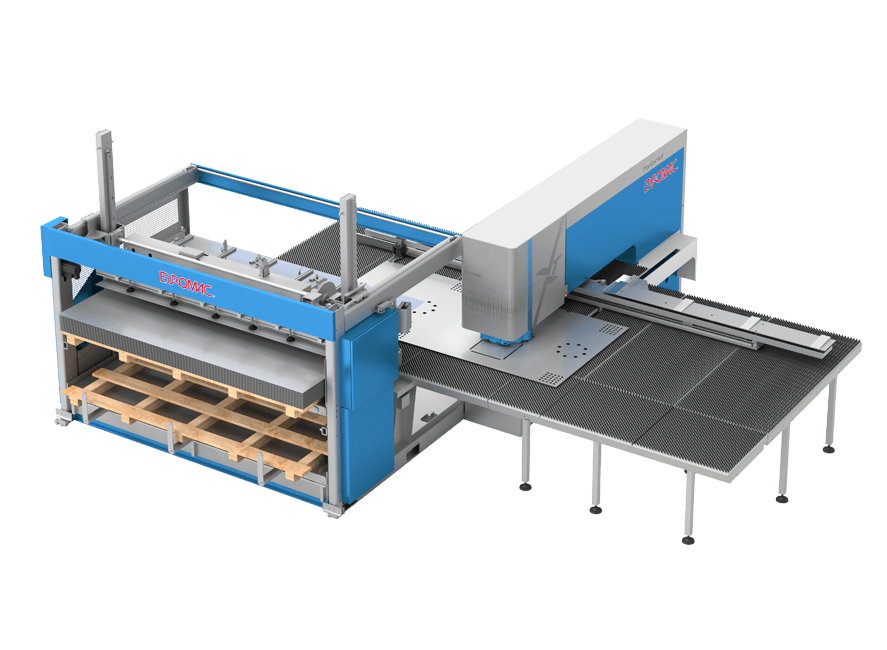

An FX Bend is, instead, designed to require minimal maintenance. Being an electric machine, it does not require oil changes and, having fewer moving parts, it suffers less wear and tear.

What is the cost of maintaining an FX Bend machine? Practically none at all.

And what about the right number of machine downtimes? Zero

Every machine downtime, especially if not planned, entails very high costs.

Your production stops, your staff cannot perform other tasks, a delay may jeopardise the relationship with your customer.

So how much does a one-hour downtime cost? One day?

If you choose an FX Bend, you need not worry about these costs.

Our machines are designed with focus on reliability.

We use amazingly strong materials, such as Meehanite.

We prefer single-block castings to limit breakage.

We use electric motors to minimise moving parts and – consequently – wear and tear.

Now, when faced with the choice between an FX Bend and a budget machine, you have only to ask yourself whether you are actually saving money or simply selling out your future productivity.

Contact us to know what other advantages FX Bend can offer you and your business!